Toolmaking & fixture construction at MEKU - precision meets efficiency

Over 50 years of experience

Tailor-made

Certification according to

ISO 9001:2015

ISO 9001:2015

Certification according to

ISO 9001:2015

ISO 9001:2015

Customized metal solutions

Customer-oriented

Certification according to

ISO 9001:2015

ISO 9001:2015

Strong implementation

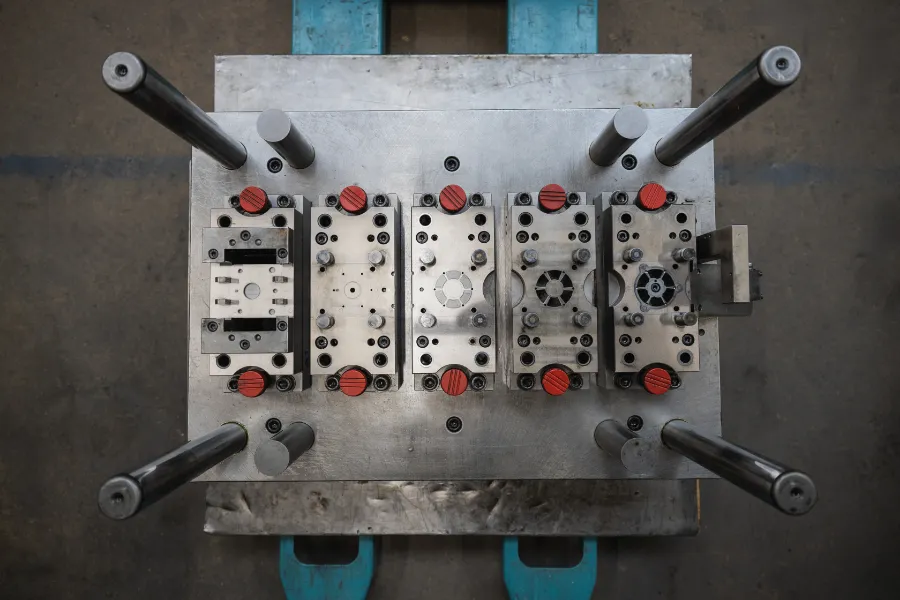

MEKU Metal Processing GmbH specializes in tool and fixture construction, with a focus on the production of precision tools and individual fixtures. By producing production tools and assembly jigs in-house, we guarantee the highest quality and efficiency. Our range of services includes CNC toolmaking, automated production processes and the manufacture of special tools that are specially tailored to our customers' requirements. We rely on advanced metalworking and material processing.

Our industrial manufacturing solutions are used, among other things, in tool and fixture construction for the automotive industry, where maximum precision and fast response times are required. Certificates such as ISO 9001 underline our commitment to quality and process optimization in manufacturing.

Our industrial manufacturing solutions are used, among other things, in tool and fixture construction for the automotive industry, where maximum precision and fast response times are required. Certificates such as ISO 9001 underline our commitment to quality and process optimization in manufacturing.

Talk to us, we will help you:

From prototype to series production: tools for every application

MEKU supplies custom-fit components for demanding applications.

- Mechanical engineering

- Automotive industry

- Chemical industry

- Aerospace industry

- Pharmaceutical industry

- Energy industry

- Food industry

- Construction industry

- Medical technology

- Water and waste water industry

Talk to us, we will help you:

Efficiency through integrated production processes

Tool and fixture construction is the backbone of MEKU Metal Processing GmbH. We manufacture tools and fixtures for the production of stamped and bent parts as well as complex assemblies. Our in-house manufacturing techniques for fixtures and tool design ensure precise CNC machining and a high degree of process optimization in production. Our production facilities and machine tools guarantee the highest quality and security of supply, demonstrating our commitment to excellence in precision manufacturing.

Precision starts with the tool

MEKU Metal Processing GmbH offers a wide range of toolmaking solutions, from forming tools and modular complete cutting tools to high-performance progressive tools. We use low-wear carbides and coated tool steels that are reliable even at high cycle rates and with demanding materials. We manufacture jigs, fixtures and prototypes in-house, which enables a fast market launch. Thanks to individual manufacturing solutions and close cooperation between design and production, we guarantee on-time delivery for industry, energy technology and the series production of complex metal components.

Special tubes

Welded components

Stainless steel sheet metal processing

Talk to us, we will help you:

Why MEKU?

Tool and fixture construction forms the foundation of MEKU Metal Processing GmbH and ensures product quality. We manufacture bending tools, tube forming tools, overall cutting tools and high-performance progressive stamping tools with carbide cutting inserts and coated tool steels. Thanks to short coordination paths and the expertise of our toolmakers, we can quickly provide prototypes and samples for series production. Our solutions also integrate automated manufacturing processes into toolmaking, which guarantees efficient fixture production and on-time delivery.

Your benefits from our in-house toolmaking

- Maximum process reliability thanks to in-house tool production

- Time and cost savings due to elimination of external dependencies

- High flexibility for short-term adjustments and repairs

- Fast prototype and sample production for shorter development cycles

- State-of-the-art tool concepts with wear-resistant cutting inserts made of carbide or coated tool steels

Questions and answers on the subject of tool and fixture construction

Tool and fixture construction is crucial for precise manufacturing processes. It includes the manufacture of tools and devices that are used in the production of parts and components. At MEKU Metal Processing GmbH, we rely on innovative technologies to provide efficient solutions for the industry. In this area, questions often arise about the techniques used and the differences between tool and fixture construction.

Contact us

MEKU Metal Processing GmbH

We look forward to hearing from you. Find out more about the extensive development and production options we can offer you.

Address

Robert-Bosch-Straße 4 D-78083 Dauchingen Germany

Send request:

Tool and fixture construction

Just send us a short message and we will be happy to answer your questions by phone or e-mail.