Punching & laser processing at MEKU - precision from batch size 1

Over 50 years of experience

Tailor-made

Certification according to

ISO 9001:2015

ISO 9001:2015

Certification according to

ISO 9001:2015

ISO 9001:2015

Customized metal solutions

Customer-oriented

Certification according to

ISO 9001:2015

ISO 9001:2015

Strong implementation

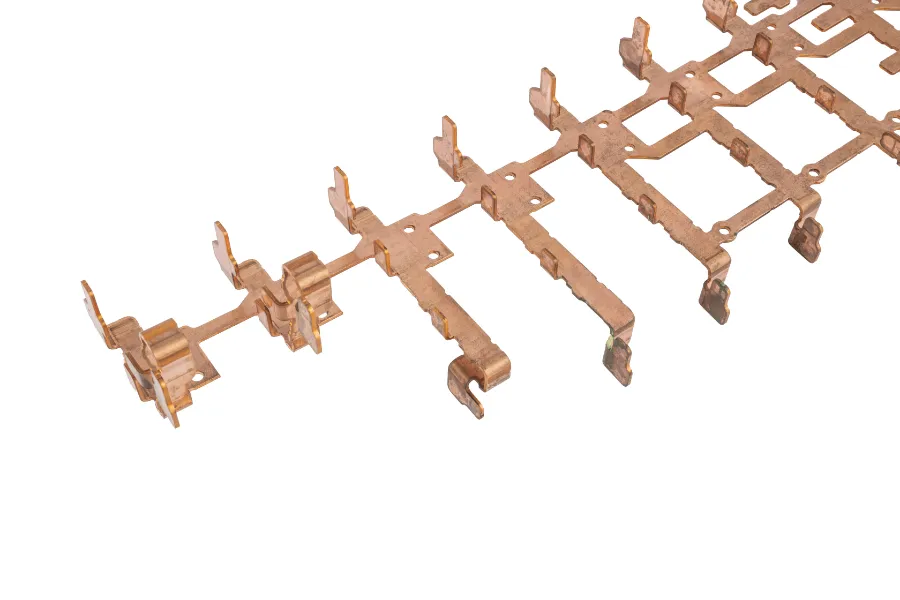

MEKU Metal Processing GmbH offers you modern punching and laser processing - from batch size 1 to series production. We use high-performance technologies to process large-format sheet metal, coil or strip products as well as precise insert and strip cuts. Whether aluminium, copper, stainless steel, high-alloy or high-temperature steels and nickel-based materials - we provide you with individual sheet metal solutions for the highest demands in a wide range of industries. Our flexibility, our cost awareness and our consistent quality assurance make us a reliable partner for sophisticated sheet metal production

Talk to us, we will help you:

Versatile use for industry, combustion technology & energy solutions

MEKU supplies tailor-made components for demanding applications - from large industrial plants to high-temperature-resistant components for combustion and energy systems.

- Mechanical engineering

- Automotive industry

- Chemical industry

- Aerospace industry

- Pharmaceutical industry

- Energy industry

- Food industry

- Construction industry

- Medical technology

- Water and waste water industry

Talk to us, we will help you:

High-tech punching and laser process

We process materials such as aluminum, stainless steels, brass, copper and copper alloys, through to high-alloy and high-temperature resistant austenitic and ferritic steels as well as nickel-based materials, which are usually used in turbine construction.

Depending on the geometry and quantity of the finished product, we process large-format sheets, coil or strip products through to strip or insert blanks.

The precise welding of high-alloy and high-temperature steels and nickel-based alloys for firing systems is one of our core competencies. Our welds are used successfully all over the world and under the most adverse conditions.

Depending on the geometry and quantity of the finished product, we process large-format sheets, coil or strip products through to strip or insert blanks.

The precise welding of high-alloy and high-temperature steels and nickel-based alloys for firing systems is one of our core competencies. Our welds are used successfully all over the world and under the most adverse conditions.

Customer-oriented communication & short response times

As experts for a wide range of applications, we develop efficient components, assemblies and systems for our customers. The targeted development work is based on the creativity and experience of our development team.

Flow and thermodynamic processes can be carried out using CFD simulations, including result validation in our test laboratory, in order to be able to master even complex tasks in the field of energy and combustion technology.

A particular advantage is the possibility of cross-company cooperation within the Group, as we can draw on specialist knowledge from other sectors. We also cooperate intensively with university institutes and other scientific institutions.

Flow and thermodynamic processes can be carried out using CFD simulations, including result validation in our test laboratory, in order to be able to master even complex tasks in the field of energy and combustion technology.

A particular advantage is the possibility of cross-company cooperation within the Group, as we can draw on specialist knowledge from other sectors. We also cooperate intensively with university institutes and other scientific institutions.

Special tubes

Welded components

Stainless steel sheet metal processing

Talk to us, we will help you:

Why MEKU?

As we have extensive expertise in the areas of design, prototyping and toolmaking, we have ideal opportunities for the rapid implementation and optimization of our developments.

Customer-oriented project management accompanies you from the planning phase through the entire course of the project right up to series production.

Our design engineers work with the CAD programs Autodesk Inventor and AutoCAD Mechanical. The flexible IGES, STEP and DXF interfaces are available for data exchange.

Customer-oriented project management accompanies you from the planning phase through the entire course of the project right up to series production.

Our design engineers work with the CAD programs Autodesk Inventor and AutoCAD Mechanical. The flexible IGES, STEP and DXF interfaces are available for data exchange.

Your advantages at a glance

- Maximum flexibility from batch size 1 - Whether a single piece or large series - we deliver quickly and precisely.

- High-tech punching and laser processes - State-of-the-art technologies guarantee clean cuts, tight tolerances and repeatable quality - even with complex geometries.

- Wide range of materials - processing of lightweight and special materials - from aluminum and stainless steel to high-alloy and high-temperature resistant materials and nickel alloys

- Premium quality thanks to integrated QM - quality assurance begins with the inquiry and accompanies the entire process through to on-time delivery

- Customer-oriented communication & short response times - your contact throughout the entire project - reliable, open and solution-oriented

Contact us

MEKU Metal Processing GmbH

We look forward to hearing from you. Find out more about the extensive development and production options we can offer you.

Address

Robert-Bosch-Straße 4

D-78083 Dauchingen

Germany

Send request:

Stamping & laser processing

Just send us a short message and we will be happy to answer your questions by phone or e-mail.